Galvo Scanner for 3D Printing and Ingredient Manufacturing

Galvo Scanner for 3D Printing and Ingredient Manufacturing

Blog Article

A Comprehensive Overview to Various Kinds of Galvo Scanners and Their Applications

Galvo scanners, known for their speed and precision, are important to a range of sectors from manufacturing to clinical technology. The trip to selecting the optimal galvo scanner for your operational needs begins with understanding these subtleties.

Fundamental Introduction of Galvo Scanners

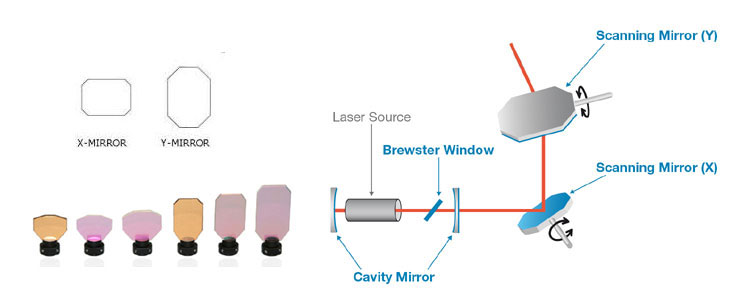

Galvo scanners, short for galvanometer scanners, are precision tools used to guide laser light beams properly and rapidly across a designated area. Essentially, a galvo scanner consists of a tiny, lightweight mirror attached to a galvanometer, which is an electromechanical gadget that gauges electric present by deflection of a needle.

The core principle behind galvo scanners is the quick and precise control of the mirror's angle, which in turn transforms the direction of the laser beam of light. This is attained via a closed-loop responses system that makes sure the mirror's setting is continually kept an eye on and changed for accuracy. The feedback system comprises position sensors, control electronic devices, and high-performance electric motors, providing phenomenal responsiveness and accuracy.

Galvo scanners stand out in applications needing intricate and repetitive laser activities, such as laser engraving, cutting, and medical imaging. Their ability to run at broadband without sacrificing accuracy makes them vital in situations demanding both effectiveness and precision.

Types of Galvo Scanners

When discovering the types of galvo scanners, it's crucial to understand that variations are mostly based on their style, application demands, and performance specs. Normally, galvo scanners can be classified into dual-axis and single-axis models.

Dual-axis galvo scanners, on the other hand, supply two-dimensional control of the light course. This makes them crucial in even more facility applications like laser light programs, 3D printing, and clinical imaging. Dual-axis versions are generally equipped with two mirrors and equivalent galvanometers, enabling dynamic control over both X and Y collaborates.

Trick Features to Take Into Consideration

When choosing a galvo scanner for your certain application,A number of key attributes should be carefully examined. Rate is a critical feature, as it identifies the scanner's capability to take care of high-frequency tasks effectively. The rate is usually determined in regards to action time and the maximum number of points per 2nd the scanner can deal with.

An additional important attribute is the scanner's variety of motion, which suggests the optimum angular variance it can accomplish. A broader variety gives higher flexibility yet may need a lot more advanced control systems. Thermal stability also needs focus, as temperature variations can influence performance; thus, choose for scanners with durable thermal monitoring systems.

Industry-Specific Applications

In various markets, galvo go right here scanners play a critical function by enhancing accuracy and efficiency in specialized applications. In useful reference the medical field, galvo scanners are indispensable to laser surgical procedures and ophthalmic treatments, where high-speed, accurate light beam positioning is essential. These tools allow minimally intrusive surgical procedures by precisely targeting tissue, thus decreasing recovery times and enhancing person end results.

In production, galvo scanners are crucial for laser engraving, cutting, and welding. Their ability to promptly and properly straight laser beam of lights makes sure top notch coatings and complex describing, which is important for the production of facility components in automotive, aerospace, and electronics sectors. The textile sector additionally profits from galvo scanners in fabric cutting and inscription, providing both rate and precision in processing varied products.

Choosing the Right Galvo Scanner

Selecting the proper galvo scanner is a critical choice that rests on a number of key factors, including application demands, efficiency specs, and budget plan restrictions. Initially, plainly specify the application requirements. Whether the scanner is intended for laser engraving, clinical imaging, or 3D printing, each application requires specific efficiency features such as precision, speed, and resolution.

Second, consider the efficiency specifications. Criteria like scan angle, feedback time, and thermal stability are vital (galvo scanner). A high-speed galvo scanner with a broad scan angle is suitable for large-area marking, while applications requiring fine information may focus on high resolution and accuracy

Third, represent spending plan constraints. High-performance galvo scanners come with a significant investment, however their lasting benefits can outweigh preliminary prices. Review the overall price of possession, consisting of upkeep, to make certain the selected scanner gives value over its life-span.

Conclusion

Recognizing the varied kinds of galvo scanners straight from the source and their one-of-a-kind capabilities is vital for optimizing performance throughout various industries. Single-axis and dual-axis models satisfy various operational complexities, while high-speed and high-precision variations attend to specific needs in production, fabrics, medical areas, and 3D printing. Mindful option based upon the special attributes and application requirements of each kind of galvo scanner makes certain boosted efficiency and accuracy, therefore significantly improving general operational end results.

Galvo scanners, brief for galvanometer scanners, are accuracy tools utilized to guide laser beam of lights precisely and swiftly across a designated area.When exploring the types of galvo scanners, it's important to comprehend that variations are primarily based on their design, application demands, and efficiency specifications. Each kind of galvo scanner is therefore distinctively customized to meet particular functional demands, ensuring optimal efficiency throughout numerous applications.

The precision of a galvo scanner directly influences the high quality of the output, making it crucial to think about the scanner's capability to maintain high-resolution efficiency (galvo scanner). Careful option based on the one-of-a-kind functions and application demands of each kind of galvo scanner ensures enhanced effectiveness and accuracy, therefore significantly enhancing general functional results

Report this page